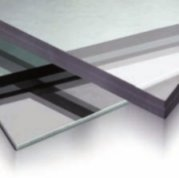

PC Polycarbonate

Amorphous engineering transparent thermoplastic.

Model making, medical technology, photo technology, household appliances, automotive industry, precision engineering, mechanical engineering.

Amorphous engineering transparent thermoplastic.

Model making, medical technology, photo technology, household appliances, automotive industry, precision engineering, mechanical engineering.

Transparent, easy to weld and bond, great heat deformation resistance, good electrical insulation, resistant to cleaning agents, many solvent and acids, tough and strong, easy to machine and easy to polish

| Properties | Unit | Test method DIN EN ISO/ASTM | Value | ||

| Mechanical | |||||

| Density | g/cm3 | 527 / D792 | 1,20 | ||

| Tensile strength at yield | MPa | 527 / D638 | 60 | ||

| Tensile strength at break | MPa | ||||

| Elongation at breaк | % | 527 / D638 | |||

| Modulus of elasticity in tension | MPa | 527 / D638 | 2300 | ||

| Modulus of elasticity in flexure | MPa | 178 / D790 | |||

| Ball indentation hardness | MPa | 2039 / 1 | 100 | ||

| Impact strength | kJ/m2 | 179 / D256 | No br. | ||

| Creep rupture strength after 1000 hrs with static load | MPa | 48 | |||

| Time yield limit for 1% elongation after 1000 hrs. | MPa | 18 | |||

| Coefficient of friction against hardened and ground steel p=0,05 N/mm2, v=0,6 m/s | —– | 0.52-0.58 | |||

| Wear conditions as above | μm/km | 22 | |||

| Thermal | |||||

| Crystalline melting point | °C | DIN 53 736 | |||

| Glass transition temperature | °C | DIN 53 736 | 148 | ||

| Heat distorsion temperature Method A Method B | °C °C | R 75 R 75 | 135 140 | ||

| Max. service temperature Short term Long term | °C °C | 140 120 | |||

| Coefficient of thermal conductivity | W/(m.K) | 0.19 | |||

| Specific heat | J/(g.K) | 1.20 | |||

| Coefficient of thermal expansion | 10-5 / K | DIN 53 483 /D696 | 7 | ||

| Electrical | |||||

| Dielectric constant at 105 Hz | DIN 53 483 | 3 | |||

| Dielectric loss factor at 105 Hz | DIN 53 483 | 0.006 | |||

| Specific volume resistance | Ω . cm | DIN 60093 | 1013 | ||

| Surface resistance | Ω | DIN 60093 | 1015 | ||

| Dielectric strength 1 mm | kV/mm | ASTM 149 | 27 | ||

| Tracking resistance | 53480 | KC 1 | |||

| Others | |||||

| Moisture absorption (standart) | % | 62 | 0.15 | ||

| Water absorption at saturation 230 C | % | 62 | 0.36 | ||

| Resistance to hot water, washing soda | Not resistant | ||||

| Flammability (UL standart 94) | HB | ||||

| Resistance to weathering | UV resistance | ||||

Insulators, plugs, housing parts, masking covers, optical components, transparent models, sight glasses, weather protection parts, plug strips and etc.